Concrete Base

Shanette requires a concrete base for all buildings. A properly built concrete base is well worth the cost and effort as it will ensure your investment is protected from the elements.

We will supply you with a fully-detailed base drawings for the specific building you are ordering- so please ask the sales team. A Shanette supplied base drawing is essential, when carrying out the base works to ensure the correct size of base is built. All other drawings on this website are for guidance purposes only.

There are 3no. main methods to choose from, depending on the type and size of your building, your site access and most importantly the soil conditions of the proposed area.

- Option 1: Overhang Method

- Option 2: Insulated Overhang Method

- Option 3: Rebated Method

Each method delivers the same end result, when properly built, but choosing the correct method for your building depends on different factors and design constraints with each method having its advantages.

Whichever base you decide to put down please keep outer base measurements 300mm out from a boundary wall or fence.

The concrete base is not included in any standard building price. Shanette do not carry out ground works nor do we include these services in our prices as standard, but prices can be arranged on application.

We can supply contact details for Ground work/Base subcontractors that can do all the base preparation for you.

Shanette are not responsible for the actions or works carried out by independent contractors, and we only supply subcontractors details on request.

Concrete Base - Option 1

Overhang Base Method

The first and most popular method is what we call an “Overhang” base. As the name suggests, the wall cladding overhangs around the sides of the concrete base, finishing 30mm below the top floor level of the concrete base. The building rests on the concrete base, much like the lid of a shoebox. This is the most economical concrete base to build, created from a single pour of concrete, reducing labour costs.

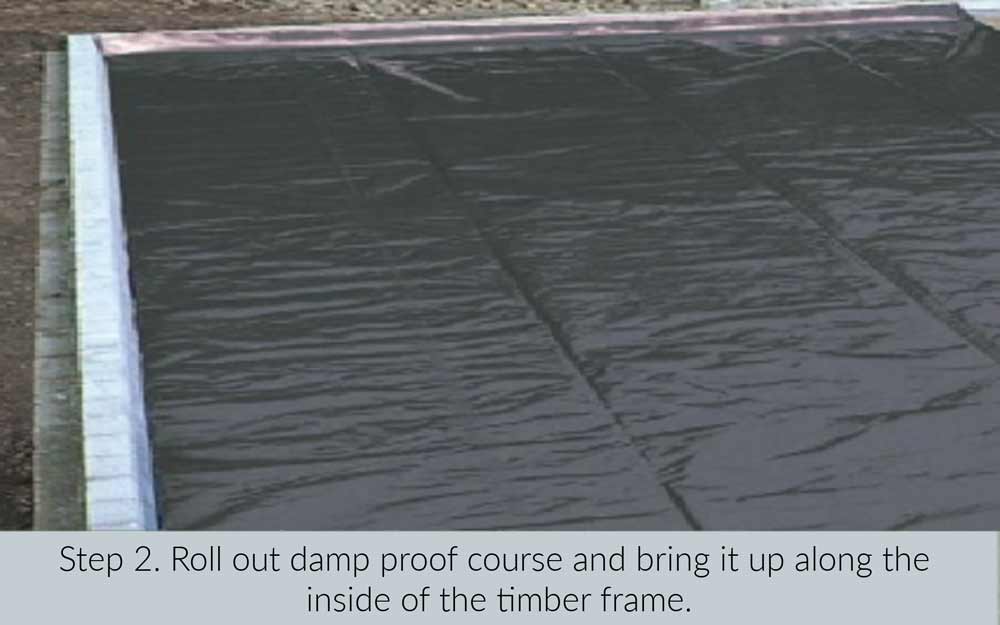

Step by step process of overhang concrete base.

The slab is poured on top of a damp-proof membrane to prevent rising damp. This base type is suitable for nearly all ground conditions, whether soft, newly filled, or an existing yard that may be uneven and requires a concrete slab for the installation of a new Shanette building.

The top floor level of an “Overhang base” needs to finish higher than the surrounding ground to allow the wall cladding to hang down 30mm past the top of the base. Once installed, all buildings are anchored to the concrete slab using certified concrete through bolts.

A “Shanette”-supplied base drawing is essential to ensure the base is the correct size for your building. The base must be 100% square to ensure the building fits securely over it. There is no margin for error when building an Overhang base! We will supply the required base drawings for your specific unit but please find a sample for guidelines purposes below. ASk your sales agent for the correct drawing for your unit when ordering.

Sample Overhang Concrete Base Drawing For Guidline Purposes Only and Step by Step Guide

Concrete Base - Option 2

Overhang Method with Insulation and 2nd pour finish floor

The second most popular method is the ‘Insulated Overhang base,’ specifically designed for insulated buildings requiring an insulated floor. Similar to the standard ‘Overhang’ base, this version has the wall cladding overhanging around the sides of the concrete base, finishing 30mm below the top of the concrete base. However, in this variant, the bottom slab acts as a subfloor.

In this process, two different pours of concrete occur, with insulation sandwiched between them. The method unfolds as follows: first, a standard overhang base is prepared, and we install your building on top of it. Then, a second damp-proof membrane (DPM) is fitted, insulation boards are laid on top of the DPM, and finally, a second finishing floor screed is poured – this could be a liquid screen if required.

As with the previous method, the first slab is poured on top of a damp-proof membrane to prevent rising damp. This base type is suitable for nearly all ground conditions, whether soft, newly filled, or an existing yard that may be uneven and requires a concrete slab for the installation of a new Shanette building.

The top level of the ‘Overhang base’ must finish higher than the surrounding ground to allow the wall cladding to hang down 30mm past the top of the base. Once installed, all buildings are securely anchored to the concrete slab using certified concrete thru bolts.

A ‘Shanette’-supplied base drawing is indispensable to ensure the base is the correct size for your building. The base must be 100% square to guarantee a perfect fit. There is no margin for error when building an Overhang base! We will provide the necessary base drawings; please reach out to one of our sales team members.

Sample Overhang Base Drawing and Step by Step Guide

Reminder: We will provide you with fully detailed base drawings for the specific building you are ordering – please reach out to our sales team for assistance. A Shanette-supplied base drawing is essential when carrying out the base works to ensure the correct size of the base is constructed. It's important to note that this drawing is for guidance purposes only.

Concrete Base - Option 3

Rebated Method

The rebated base features an inner floor that is 50mm higher on the inside than the outside. This design ensures the floor is fully secured and sealed against wind and rain. All sheds are securely bolted to the concrete, ensuring their stability in place. We provide a fully detailed base drawing for your specific shed upon order – please don’t hesitate to inquire with our sales team.

The base drawing is essential in order to have the base the correct size for your shed or we have a subcontractor we recommend that can do all the base preparation for you. Shanette are not responsible for the actions or works carried out by independent contractors.

Visual of Step by Step Process of The Rebated Method

Sample Concrete Rebated Base Dawing and Step by Step Guide

We will supply you with a fully-detailed base drawings for the specific building you are ordering- so please ask the sales team. A Shanette supplied base drawing is essential, when carrying out the base works to ensure the correct size of base is built. All other drawings on this website are for guidance purposes only.

Concrete Base Drying Information

A concrete surface may look dry, but the slab can still contain sufficient moisture to cause problems when covered. The amount of concrete moisture can be considerable. In practical terms, several pounds of water must evaporate from every square foot of concrete for the slab to be considered adequately dry for floor finishes.

The industrial rule of thumb for estimating the drying time necessary for concrete floors to reach acceptable moisture content is 1 month of drying for each inch of concrete thickness (1mm per day). So to help the drying time in your new unit you should take the following steps:

Leave the door (s) or a window (if fitted) open for extra ventilation or Use a de-humidifier to speed up the process.

Base Contractors

Shanette are not responsible for the actions or works carried out by independent contractors.

SITE ACCESS

Please discuss site access with one of our sales team as some of our units will require crane access.